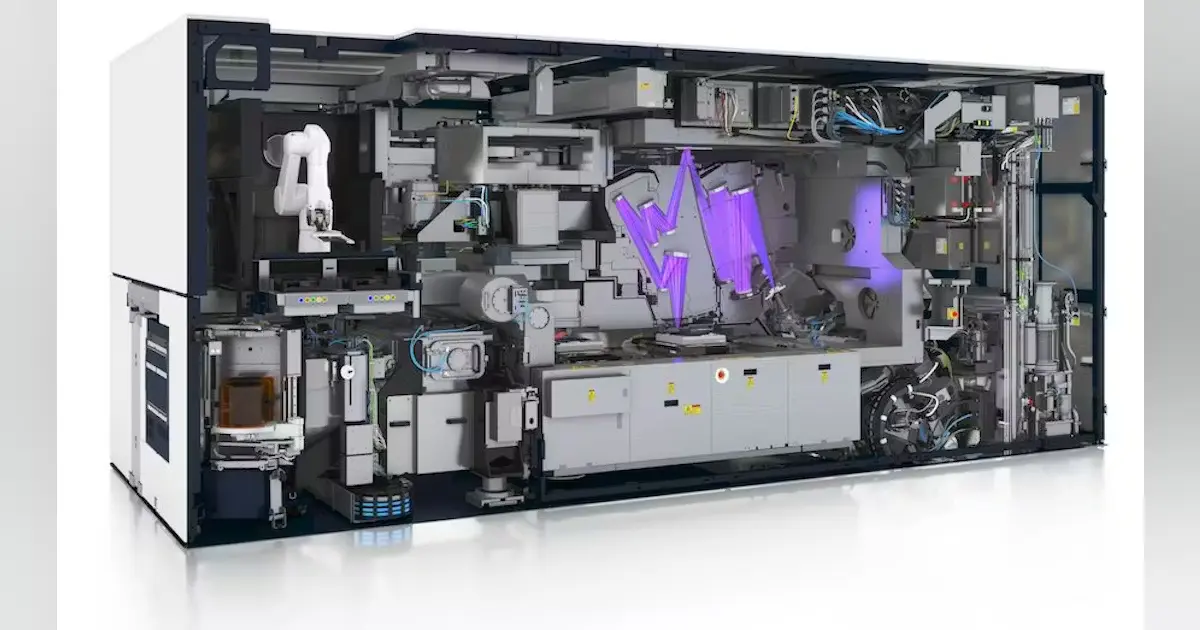

ASML TWINSCAN EXE:5200 Laser Source Featured

Project Overview

Top Summary: This project involved developing highly reliable, high-speed software components for the critical laser source system within ASML’s cutting-edge lithography machine, the TwinScan EXE:5200.

| Quick Stats | Details |

|---|---|

| Role | Software Engineer |

| Duration | Nov 2024 - Dec 2025 |

| Stack/Tools | C++, Python, Formal Verification, Computer Vision, Real-Time OS |

1. The Challenge

The next generation of lithography machines requires unprecedented precision and uptime. The laser source is a highly complex subsystem and the new EXE:5200 requires first-time-right performance when deployed in the field (first shipment happened mid-2025).

- Problem: Embedded software for highly complex systems often shows many bugs when first deployed, costing time and money in fixing and getting ready for operation.

- Goal: To design and implement a robust, laser source control software that is near faultless when delivered to the customer.

2. Solution & Technical Approach

Using formal verification software development methods control software can be systematically tested and verified during development, eliminating bugs and delivering quality.

- Model driven software engineering allows for a verified formal notation which can then be transformed into domain specific languages (such as C++), and will be used in the development of real-time control software for the laser.

- New Embedded cameras had to be added inside the laser beam path, the subsystem drivers for these cameras has been written in C++.

3. Results & Conclusion

The software components designed and developed have proven to be effective in the field, demonstrating the effectiveness Model Driven Software Engineering in the development of safety-critical systems.